Twist and Shout – The Truth About Torsion Beam Suspensions

Related Products

Share

Understanding the Basics of Rear Suspension Design

Ever wondered what's holding up the back of your car? For many vehicles on the road today, the answer is a clever piece of engineering called a torsion beam suspension. This unsung hero quietly performs its job beneath your vehicle, balancing cost-effectiveness with surprisingly decent performance.

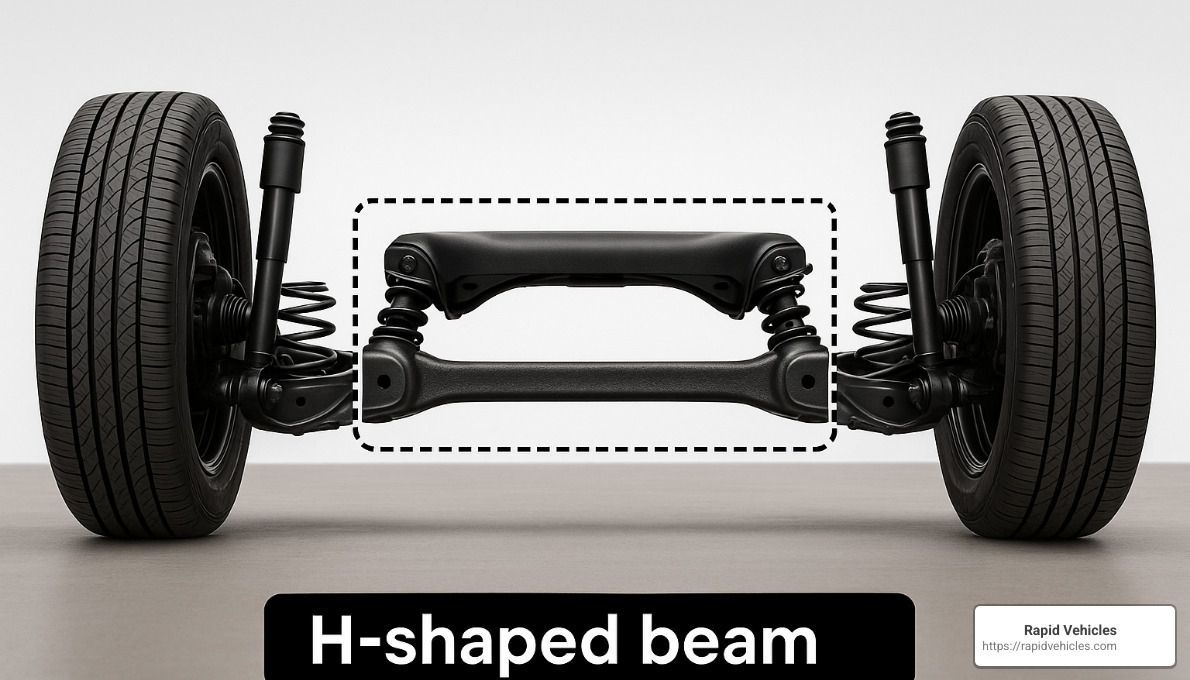

A torsion beam suspension (sometimes called twist-beam or semi-independent suspension) is neatly simple compared to its more complex cousins. It features an H-shaped or C-shaped beam connecting your rear wheels, allowing them to move somewhat independently while sharing information with each other. Think of it as siblings who have their own lives but still influence each other's decisions.

The magic happens in how this system works. When you hit a bump with one wheel, the beam twists slightly to absorb the impact, functioning as a built-in anti-roll bar. This twist action gives the system its nickname - "twist-beam" - and provides a clever compromise between fully independent and rigid axle designs.

Volkswagen helped popularize this design in the mid-1970s, implementing it across their Golf, Polo, and Scirocco models. The reason was clear: torsion beam suspensions are simpler, lighter, and less expensive to produce. According to Opel's development data, manufacturers save approximately €100 per vehicle compared to multi-link systems. That might not sound like much, but multiply it by millions of cars, and the savings become substantial.

Don't mistake simplicity for poor performance, though. Modern torsion beam designs can deliver impressive handling characteristics when properly engineered. The Peugeot 308 II, equipped with this setup, passed the challenging moose test at 82 km/h, outperforming some vehicles with supposedly superior suspension designs.

For BMW owners browsing RapidVehicles.com, understanding different suspension types provides valuable context. While your BMW likely features a more sophisticated setup, knowing how various suspension systems compare helps you appreciate the engineering choices that went into your vehicle and makes you a more informed buyer when considering your next car.

This type of suspension is particularly common in front-wheel-drive compact and subcompact cars, where maximizing interior space while keeping costs in check is crucial. The simplified design requires fewer bushings, joints, and moving parts, making it both cost-effective to produce and potentially more durable over time with fewer components that could fail.

As we dive deeper into torsion beam suspensions, you'll find why many manufacturers continue to rely on this proven design even as automotive technology advances. It's a fascinating story of engineering compromise, where simplicity often proves to be a virtue rather than a limitation.

How Torsion Beam Suspension Works

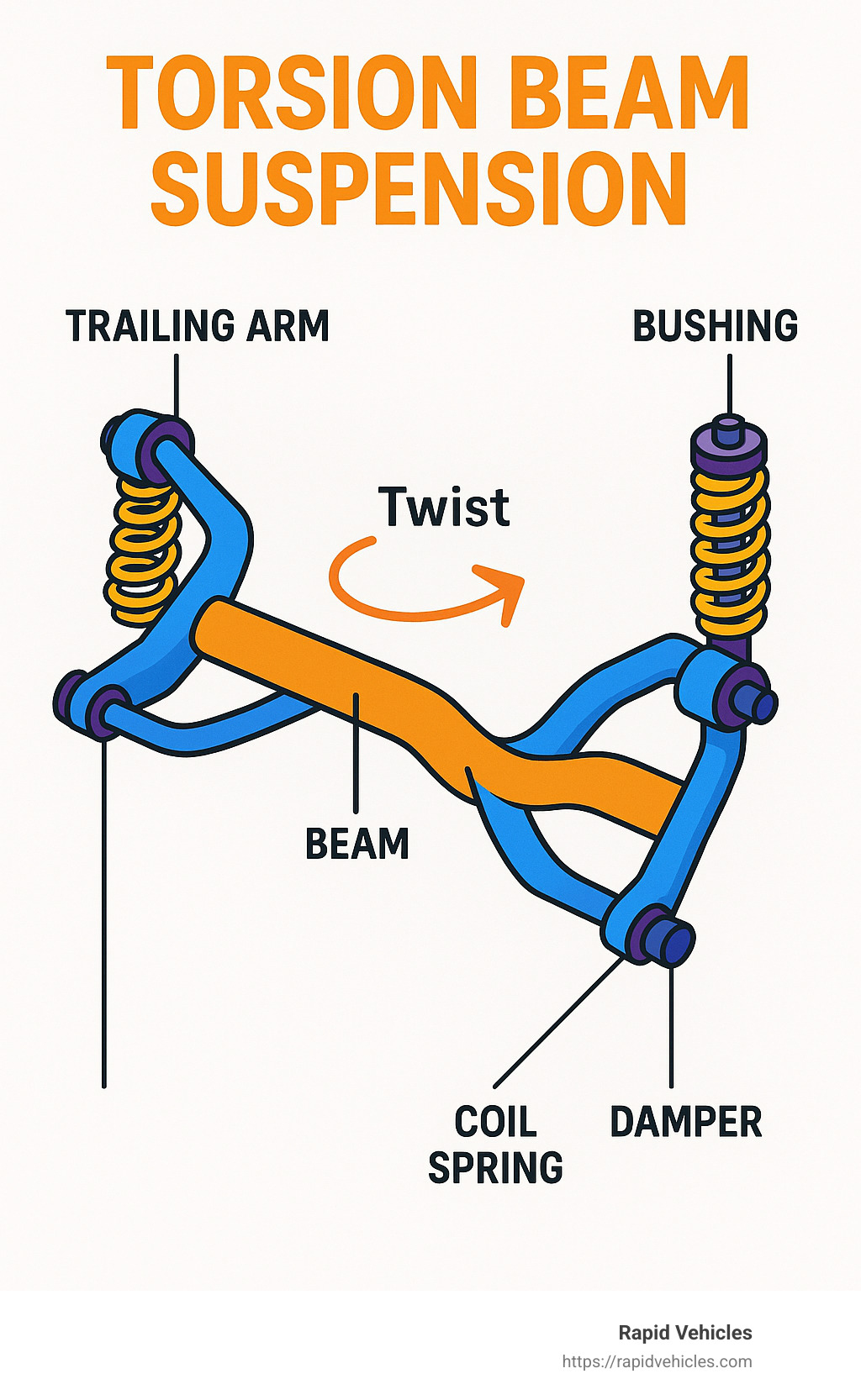

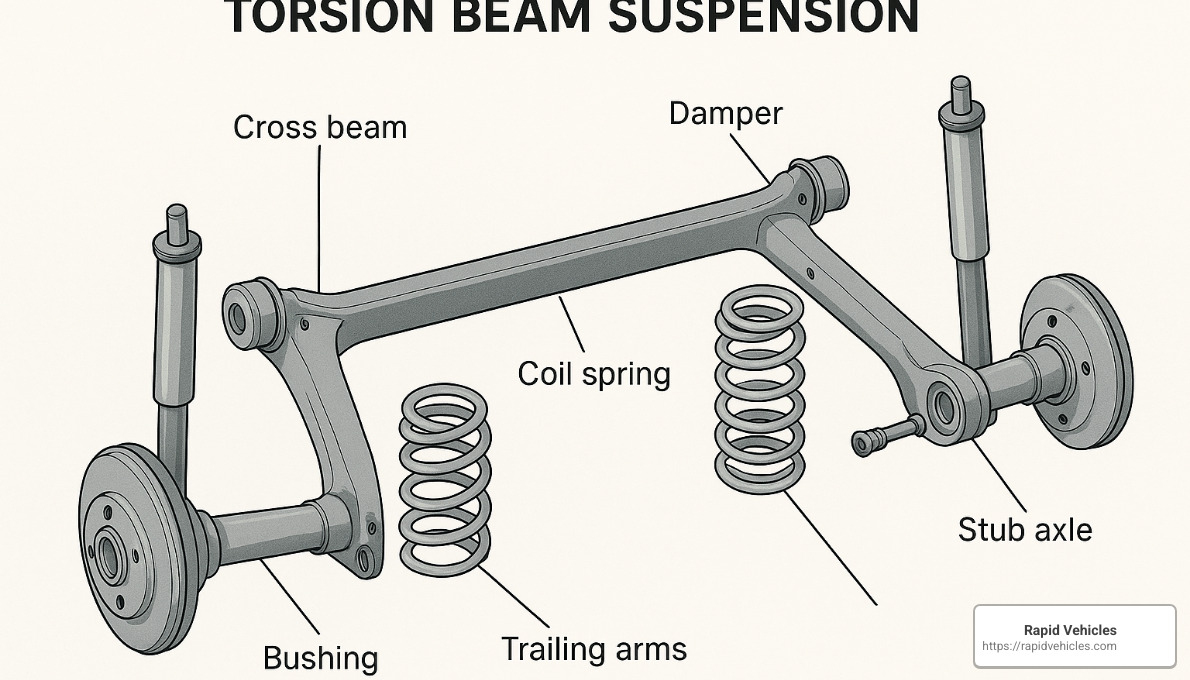

A torsion beam suspension is a marvel of clever, minimalist engineering. At its heart, it features two trailing arms joined by a cross member—the "beam" that gives the setup its name. This creates an H-shaped or sometimes C-shaped assembly, with the front ends of the arms mounted to the car’s chassis using rubber bushings and the rear wheels attached at the far ends.

What really makes this design special is how it reacts to the road. Imagine both rear wheels rolling over a speed bump at the same time. In this scenario, the entire assembly just pivots upward together at the bushings—no twisting, no drama. Both wheels move up, the beam stays straight, and everyone’s happy.

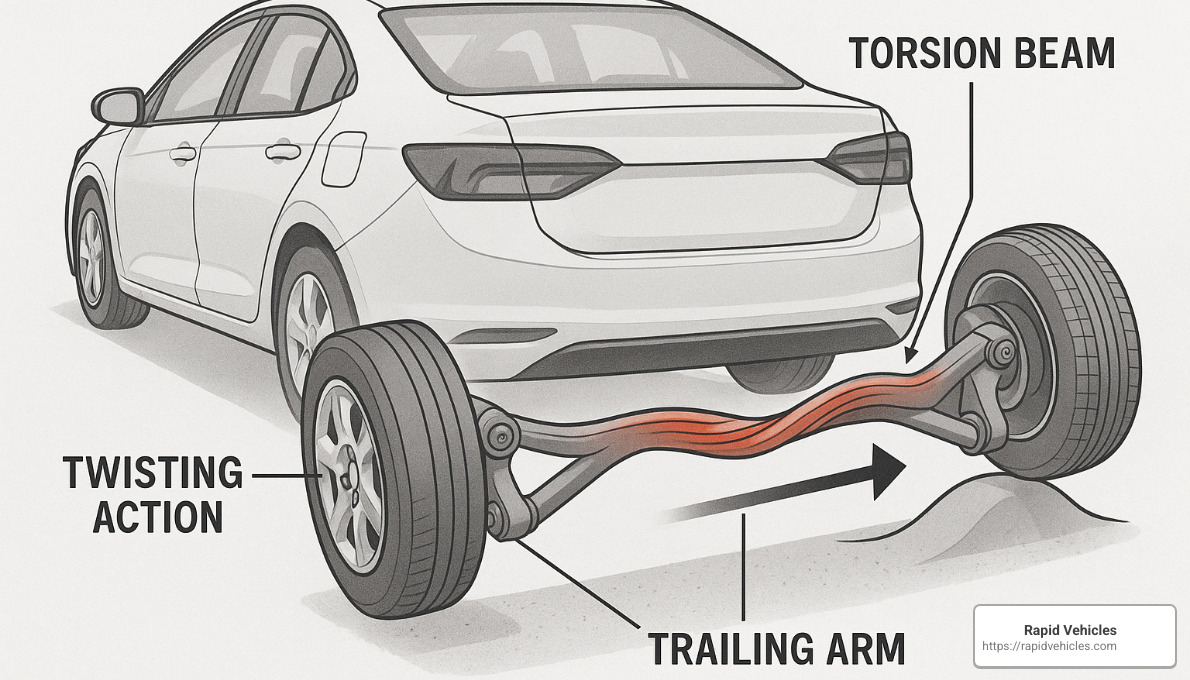

But the magic of the torsion beam suspension reveals itself when just one wheel hits a bump, or during hard cornering. Let’s say you hit a pothole with one rear wheel. The affected trailing arm wants to move up, while the other arm wants to stay put. The only way for this to happen? The cross beam has to twist—literally. This twisting action is what allows the suspension to absorb the uneven force, providing some independence between the wheels even though they’re connected.

Suspension expert Julian Edgar puts it simply: the torsion beam itself acts as a built-in anti-roll bar. So, not only does it support the car, it also resists body roll when cornering, all without needing an extra stabilizer bar bolted underneath. Less weight, fewer parts, more boot space—what’s not to like?

Let’s break it down:

- Both wheels hit a bump: The whole assembly moves up as one, no twisting.

- One wheel hits a bump or in a corner: The beam twists, resisting roll and keeping the car flatter.

The Axle That Twists – Physics 101

Here’s a little physics, minus the headache. The secret behind the torsion beam suspension is the way the cross member works like a massive torsion spring. When it twists, it stores up energy and pushes back—helping to control how much the car leans in a turn.

The “springiness” of the beam depends on its material (usually strong steel), the shape of its cross-section (often a U or V), the thickness of the metal, and how long the beam is. All these factors together decide how much the beam resists twisting.

In independent suspensions, roll stiffness mostly comes from the coil springs and an extra anti-roll bar. But here, the beam itself is the anti-roll bar. According to automotive engineer Greg Locock, the beam acts a bit like a “virtual semi-trailing arm”—there’s even a neutral twist point, almost like a hidden pivot inside the beam.

Engineers can tune the handling of the car by tweaking the properties of the beam—change the thickness, the shape, or even the steel itself, and you get a stiffer or softer ride.

Torsion Beam Suspension As Built-In Anti-Roll Bar

This is where the torsion beam suspension really shines. In most cars, you need a separate anti-roll bar to fight body lean when turning. But with a torsion beam, the cross member is the stabilizer.

Here’s how it works: Take a hard corner. The outside rear wheel compresses, the inside one extends—the cross member is forced to twist as these two sides move in opposite directions. That twist resists the body’s urge to roll over, keeping things level and improving grip.

How much resistance you get depends on the torsional rigidity of the beam, the exact spot where it wants to twist (called the twist center), and how far the beam sits from the pivots of the trailing arms. As Julian Edgar notes, moving the beam closer or farther from these pivots can shift how forces are split between twisting and bending.

Manufacturers can even add a supplemental anti-roll bar for sporty models, boosting stiffness without changing the basic design. This flexibility lets engineers fine-tune each car’s handling—whether it’s a comfy city runabout or a sharp-handling hot hatch.

So, while the torsion beam suspension might look simple, there’s a lot going on under the surface—smart physics, clever packaging, and an neat way to balance cost, comfort, and road manners.

Anatomy & Geometry: Beam, Arms, Bushings

The magic of a torsion beam suspension is in its simple, sturdy design—but don’t be fooled, there’s some clever engineering going on underneath your car. Let’s take a friendly tour of what’s actually holding up the back of so many everyday vehicles!

At the heart of every torsion beam suspension is, you guessed it, the beam itself. It’s usually made of high-strength steel, shaped like a U or a V. This isn’t just for looks—the shape helps the beam twist and bend in just the right way. The location of the shear center (where the beam naturally wants to twist) versus the area centroid (the “center of mass” for the shape) is a big deal here. It’s this clever geometry that lets the beam act as both a connector and a springy anti-roll bar.

Trailing arms come next. Think of them as the system’s sturdy arms, reaching from the chassis (where they’re mounted with bushings at the front) back to the wheel hubs. They let the wheels move up and down, keeping the car comfy over bumps while holding the wheels at the correct distance apart.

At the very end of each trailing arm, you’ll find stub axles. These are the mounting points for wheel bearings and hubs, making sure your wheels spin smoothly.

Supporting all that weight are the coil springs. They sit between the trailing arms and the car’s body, holding up the car and absorbing shocks from nasty potholes and speed bumps. Dampers (or shock absorbers) are usually tucked in right beside them, calming down any bouncing and keeping the ride smooth.

Don’t forget the compliance bushings—those thick rubber or sometimes polyurethane pieces that allow just enough flex at the mounting points. They isolate noise and vibration, and they help the suspension do its job without shaking the whole car.

Put it all together and you get a semi-independent rear suspension. It’s not as rigid as an old-school solid axle, but it’s also not as fancy as a multi-link setup. When one wheel hits a bump, the beam twists, letting each wheel move somewhat independently. But there’s still a mechanical link between them—think of it like siblings who share a room. They can have some alone time, but what one does still affects the other!

Cross-Beam Placement: Three Layout Types

Where the cross-beam sits in your torsion beam suspension makes a huge difference in how your car handles. Engineers can fine-tune a car’s feel just by shifting the beam forward or back.

- With a pivot-centered beam, the beam is close to the front bushings (where the trailing arms connect to the car). This setup acts a lot like a pure trailing arm. When only one wheel moves, the beam mostly bends instead of twisting, and camber changes are minimal. Volkswagen used this in the early Golf, giving a soft, forgiving feel.

- Shift to a mid-span beam, and the cross member sits halfway between the pivot and the wheel. This is the “goldilocks” spot—offering a good balance of comfort and sporty handling. It’s the most common style found in today’s compact cars.

- Move the beam right out to the wheel centers and now you get more camber change during cornering—almost like a semi-trailing arm system. This can boost cornering grip, but it also makes handling a bit trickier to tune.

As suspension expert Julian Edgar puts it, “Beam placement fundamentally changes the suspension’s behavior between pure trailing-arm, dead-axle, and semi-trailing-arm modes.” It’s a simple way for car companies to tweak ride and handling without reinventing the wheel—literally.

Alignment Changes: Camber, Toe, Roll-Steer in a Torsion Beam Suspension

When your suspension moves, your wheel alignment isn’t staying perfectly fixed. In a torsion beam suspension, these shifts are a natural part of the design.

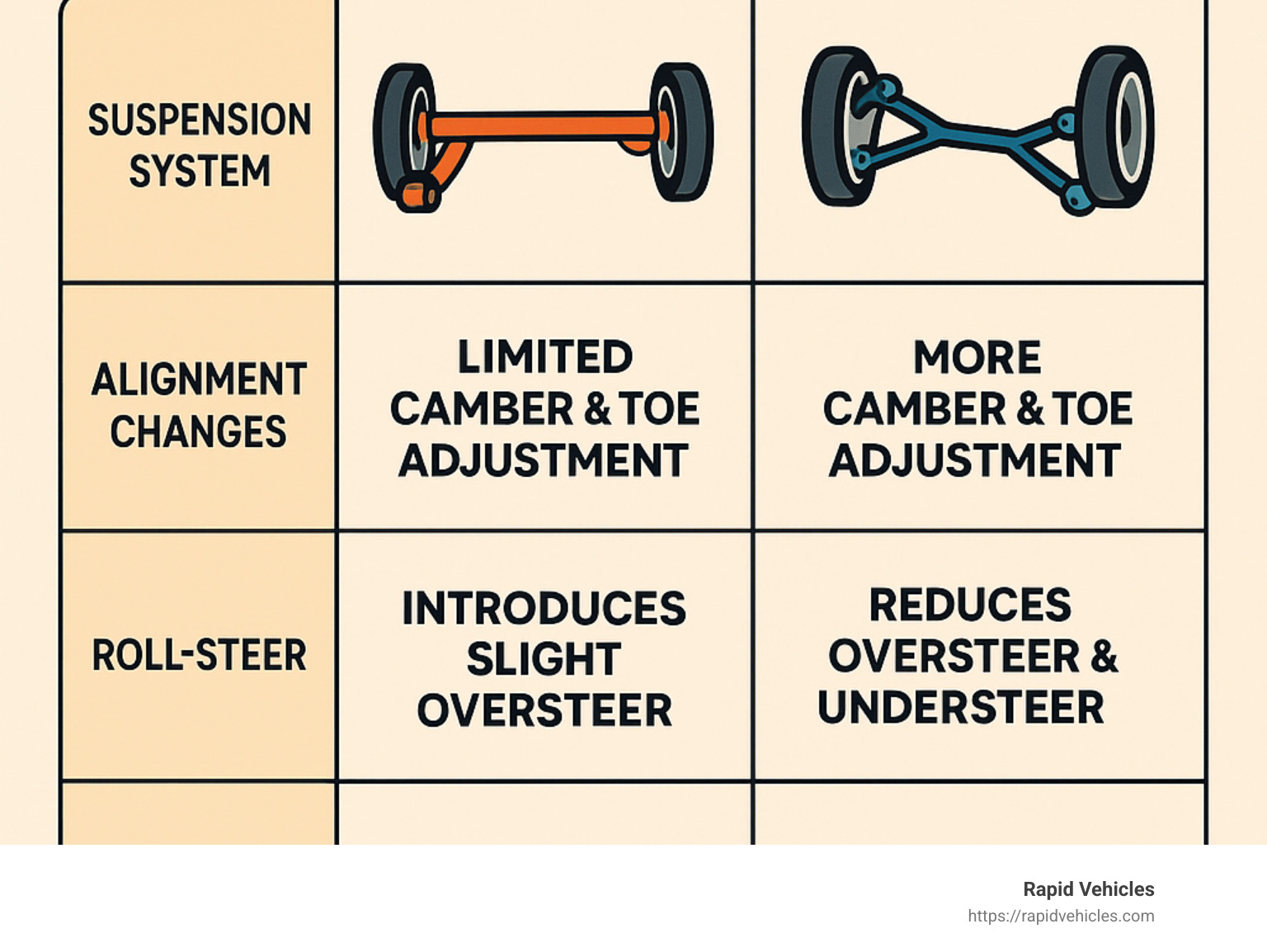

Camber changes show up mostly when only one wheel goes over a bump or during hard cornering. That wheel gains negative camber (tilting the top of the wheel inward). This can actually help with tire grip when cornering, similar to semi-trailing arm designs. With both wheels moving together (like driving over a speed bump), camber stays pretty much the same.

Toe changes are another story. When the beam compresses, the wheels tend to point outward a bit (toe-out). This can make the rear end feel lively—sometimes even a touch oversteery—especially over bumps or during spirited driving. Manufacturers use special bushings, designed to flex in specific directions, to keep this under control.

Roll-steer is a fancy way of saying: does the suspension geometry make the car steer itself a little when it leans in a corner? With a torsion beam, you can design in a bit of understeer or oversteer based on how the beam is placed and how the bushings flex.

A neat bonus: If the geometry is done right, a torsion beam suspension gives anti-lift during hard braking. That means the rear of the car resists popping up when you hit the brakes hard—keeping things stable and predictable.

Many carmakers use asymmetrical bushings that are softer in one direction than the other, so they can fine-tune how much the wheels move around when the suspension works. That’s why, if these bushings wear out, the car’s handling can start to feel weird—making maintenance important for keeping things tight and safe.

The torsion beam suspension may seem basic, but every piece and placement matters. From the U-shaped beam twisting just so, to the way the trailing arms and bushings work together, it’s all designed to deliver the best balance of cost, comfort, and cornering. With smart engineering, this simple setup punches well above its weight!

Advantages, Limitations & Comparison to Multi-Link

The torsion beam suspension has stuck around for good reason. It’s not just a relic from the past—it’s a clever solution that balances cost, simplicity, and performance, especially for smaller and front-wheel-drive cars. But, like any design, it’s not perfect. To see why automakers still love it (and where it falls short), let’s dig into its real-world pros and cons compared to more complex multi-link suspensions.

Strengths that Keep OEMs Hooked

One of the biggest attractions of torsion beam suspension is its cost efficiency. With far fewer components than a multi-link setup, manufacturing is simpler and cheaper. According to Opel, switching to torsion beam can save about €100 per car. For a company building thousands of cars a week, that adds up fast!

But lower cost doesn’t mean cutting corners. The compact layout of a torsion beam means less underfloor clutter, so designers can give you a roomier interior and a bigger trunk. This is a huge benefit if you drive a hatchback or compact car where every cubic inch matters.

There’s also the weight advantage. Less hardware means a lighter rear end. That helps with fuel efficiency and can even make the car feel more nimble. In a world of strict emissions rules, every kilogram counts.

On top of that, there’s durability to consider. With fewer bushings and moving parts, there’s just less to wear out. Maintenance is easier, too—fewer things to check and replace. It’s not uncommon for a torsion beam to last the life of the car with only minimal attention.

And here’s a neat trick: the beam itself acts as a built-in anti-roll bar. There’s often no need for a separate stabilizer, which saves even more weight and cost. As one engineer put it, the cross-member “does double duty” by linking the wheels and resisting body roll.

Weak Spots You Should Know

Of course, torsion beam suspension isn’t perfect. The big limitation is adjustability. Unlike a multi-link setup, you can’t really tweak camber, toe, or track. The geometry is mostly “what you see is what you get.” If the beam gets bent in a bump or accident, realignment isn’t easy—or sometimes even possible—without swapping parts.

Ride comfort is another area where you might notice a difference. Because the wheels are semi-connected, a sharp bump on one side can send a jolt across to the other. On rough roads at low speeds, you may feel a bit more vibration than with an independent rear end.

Handling can also show some quirks. In hard corners, a stiff torsion beam might actually lift the inside rear wheel—so yes, your car could be “three-wheeling” through sharp turns! For most drivers it’s not a safety issue, but it can make the car feel less solid or playful at the limit.

There’s also a tendency toward oversteer—that’s when the back of the car wants to step out, especially if you hit a mid-corner bump or lift off the throttle suddenly. This happens because the suspension naturally toes the wheels outward as it compresses. Engineers try to control this with special bushings, but it’s always a factor.

And don’t forget weld fatigue. Over time, especially if you drive on rough roads or push the car hard, the welded joints on the beam can wear out. Good quality control at the factory matters here.

Torsion Beam Suspension vs Independent Rear – Who Wins?

So, does torsion beam suspension win out over an independent rear end? The answer honestly depends on what you want from your car.

For most daily drivers—especially in small hatchbacks and economy cars—the difference may be tiny. Most folks won’t notice any shortcomings in normal driving. As one enthusiast put it, “99% of drivers won’t spot the difference between a well-tuned torsion beam and a fancy multi-link.”

But if you’re chasing lap times or want the most refined ride, multi-link has the edge. Independent setups allow for more precise tuning, better wheel control over bumps, and more consistent grip. They also give engineers more freedom to balance ride and handling for everything from comfort to racing.

That said, a well-tuned torsion beam can hold its own. The Peugeot 308 II, with its twist-beam rear, managed an 82 km/h pass in the moose test—nearly world-class. The Renault Megane R26, also with a torsion beam, set blistering Nürburgring lap times that shamed cars with “fancier” suspensions.

It comes down to priorities. If you care most about affordability, simplicity, and interior space, a torsion beam suspension is a great choice. If ultimate handling, adjustability, and comfort are at the top of your list (and you’re willing to pay more), independent rear suspension is still king.

For a deep dive into the real-world differences, check out Torsion beam vs independent rear suspension, or browse our own RapidVehicles.com blog for more insights and parts to help you get the best from your BMW or daily driver.

In the end, whichever suspension you choose, knowing what’s under your car is the first step to making the right upgrades—and enjoying every drive.

Tuning, Modifying & Recent Innovations

Even though a torsion beam suspension is known for its simplicity, that doesn't mean it's stuck in the past. In fact, this humble setup hides a surprising amount of tuning potential. Whether you're chasing sharper handling or just want to add a bit of spice to your daily commute, there are plenty of ways to make your twist-beam car feel fresh—and even rival pricier, more complex suspensions.

Budget Mods: Springs, Bushings, Bars

Let’s start with the basics—simple upgrades that deliver real-world results without wiping out your wallet.

Stiffer rear springs are a classic first step. As Julian Edgar famously shared about his Honda Insight, just switching to slightly stiffer Daewoo Matiz springs gave him noticeably better roll control. The ride didn’t turn teeth-rattling harsh, either—a win-win. The swap itself is straightforward: safely jack up the car, remove the damper bolts, swap the springs, and reassemble. If you’re hunting for the perfect spring, look for ones with thicker wire or just a coil or two less than stock.

Next up: bushings. The bushings that join the trailing arms to your car’s chassis might be small, but they have a big say in how your car handles. Some folks swear by solid polyurethane bushings for a firmer feel, but as Edgar cautions, sticking with high-quality standard replacements is usually best unless you love experimenting. Many stock bushings are designed to flex just the right amount in certain directions, helping keep unwanted toe changes under control. If you do upgrade, make sure the new bushings don’t throw off this balance.

Don’t forget about the anti-roll bar. The beauty of the torsion beam is that the cross beam itself acts as an anti-roll bar. But you can up the ante by either fitting a thicker internal bar or adding a bolt-on external one. And here’s a fun physics fact: a small jump in bar diameter means a much bigger jump in stiffness, thanks to the “fourth-power” rule. So, even a modest upgrade delivers a noticeable difference. Brands like Cusco offer bolt-on bars—easy to install and great for dialing in that extra cornering confidence.

Watts Linkage & Hybrid Designs

If you’re craving something a bit more advanced, take a look at how manufacturers have been pushing the torsion beam suspension to new heights with clever innovations.

One standout is the Watts linkage, as seen on the Opel Astra. For just a tiny bump in cost, this setup adds a central pivot and links that guide the beam laterally. The result? Much better control during fast cornering and rough roads. The Watts linkage keeps the rear wheels pointing straight, even when the car is loaded up in a turn—solving one of the main weaknesses of basic twist-beam designs. If you’re handy, there are even retrofit kits (and detailed guides) out there for many popular models.

Another fresh idea is the compound crank design, which is just a fancier take on the torsion beam with extra links to keep alignment changes in check. Some newer cars have variable-thickness beams—thicker in high-stress areas, thinner elsewhere—for progressive stiffness. This means the suspension can be soft for small bumps but firm up for hard cornering. Pretty clever!

You might also hear about toe-control links. These add-ons help keep toe angles consistent as the suspension moves, reducing that “rear end wants to wander” feeling during spirited driving.

As one engineer put it, “Adding a Watts linkage to a torsion beam can outperform some multi-link setups, and for way less money.” Not bad for a design that started out as a budget solution!

The world of torsion beam suspension keeps evolving, with mods and factory tricks that close the gap between affordable simplicity and sharp handling. Whether you’re tweaking springs in your driveway or admiring the latest Watts-linked hot hatch, there’s more potential here than most people realize. And if you’re looking for parts or inspiration, RapidVehicles.com has you covered with a wide selection of upgrades for BMWs and other favorites.

Real-World Cars, Maintenance & Buying Tips

The torsion beam suspension has found its way into a diverse range of vehicles, from basic economy cars to surprisingly capable performance models. Understanding which cars use this suspension type and how to maintain it can help buyers make informed decisions.

Economy Heroes & Hot-Hatch Surprises

Volkswagen Golf: The Golf popularized the torsion beam suspension in Europe in the mid-1970s and continued to use variations of this design for generations. While higher-performance variants eventually switched to multi-link setups, many standard Golf models retained the torsion beam for its cost and packaging benefits.

Peugeot 308 II: This compact hatchback demonstrated that a well-executed torsion beam suspension could deliver impressive handling. It passed the challenging moose test at 82 km/h, just shy of the world record.

Suzuki Swift Sport: Despite its modest price, the Swift Sport has earned a reputation for nimble handling and driver engagement. As one forum contributor noted, "Both the Suzuki Swift and Swift Sport, despite using torsion beam rear suspensions, are celebrated for their dynamic handling."

Hyundai i20 N: This modern hot hatch employs a torsion beam rear suspension yet delivers impressive performance. As one reviewer observed, "The i20 N's torsion beam rear end produces a firm ride in town but settles at speed."

Renault Megane R26: This performance-focused hot hatch achieved impressive Nürburgring lap times despite competing against vehicles with more sophisticated suspension designs.

First-generation Toyota Prius: Even Toyota's groundbreaking hybrid used a torsion beam rear suspension to maximize interior space and minimize complexity.

These examples demonstrate that a torsion beam suspension, when properly engineered, can deliver performance that belies its relatively simple design.

Service, Repair & Durability Checklist

For those owning or considering a vehicle with a torsion beam suspension, here are key maintenance considerations:

Bushing Inspection: The bushings that connect the trailing arms to the chassis are critical wear items. Deteriorated bushings can cause alignment issues, unusual tire wear, and poor handling. Inspect these regularly, especially on higher-mileage vehicles.

Beam Integrity: Check for signs of fatigue or cracking around the beam welds, particularly on performance-oriented vehicles or those driven on rough roads.

Damper Function: Since the dampers play a crucial role in controlling the beam's movement, ensure they're functioning properly. Worn dampers can lead to excessive bouncing and poor control.

Alignment Verification: While torsion beam suspensions offer limited adjustment, it's still important to verify that the alignment is within specification, especially after accidents or significant impacts.

Spring Condition: Inspect the springs for signs of sagging or damage, which can affect both ride height and handling.

As one engineer advised, "Maintain the correct directional compliance of torsion beam bushes—softer in one direction—to preserve designed toe-control."

For buyers considering a used vehicle with this suspension type, pay particular attention to:

- Uneven tire wear (often indicates bushing issues)

- Unusual noises over bumps

- Excessive body roll during cornering

- Poor tracking on rough roads

While torsion beam suspensions are generally durable due to their simplicity, they still require proper maintenance to deliver their designed performance.

Frequently Asked Questions about Torsion Beam Suspension

Is a torsion beam always inferior to multi-link?

The short answer? Absolutely not! A torsion beam suspension isn't inherently worse than a multi-link system—it's just different, with its own unique set of trade-offs.

Think of it like comparing a Swiss Army knife to a specialized tool set. One is brilliantly compact and does many jobs reasonably well, while the other might excel at specific tasks but takes up more space and costs more.

For many everyday cars, especially compact front-wheel-drive vehicles, a well-designed torsion beam delivers surprisingly good performance while saving on cost, weight, and space. As suspension guru Paddie wisely put it, "A well-tuned torsion beam setup will beat a badly-tuned multi-link setup any time." This really highlights that engineering quality and proper tuning often matter more than the basic design.

Need proof? Look at the Peugeot 308 II with its torsion beam rear end. It passed the challenging moose test at an impressive 82 km/h—just a whisker away from the world record! For most drivers in normal driving conditions, you'd be hard-pressed to notice significant differences between a good torsion beam and a basic multi-link setup.

Can you adjust camber or toe on a torsion beam suspension?

Here's where the torsion beam suspension faces one of its biggest limitations. Unlike multi-link systems where you can tweak individual components for precise alignment, torsion beam setups offer minimal adjustment options once they leave the factory.

Your camber and toe settings are essentially "baked in" during manufacturing. It's a bit like buying a pre-custom suit versus one with adjustable features—what you see is largely what you get.

After an accident or major impact that affects alignment, your options become pretty limited:

First, you can replace damaged components with factory parts. Second, you might find specialized aftermarket parts designed with some built-in adjustment capability. In rare cases, specialized shops can actually modify the beam itself, though this isn't typically recommended.

As one straight-talking forum member put it, "Torsion beam setups cannot have rear wheel alignment corrected after impact." That's something worth considering if you frequently drive on rough roads or hit the track.

For typical street driving, this limitation rarely causes problems since the factory alignment is already optimized for normal use. However, if you're a performance enthusiast looking to dial in specific handling characteristics, this lack of adjustability might feel restrictive.

Does a torsion beam harm ride comfort in electric or hybrid cars?

This is a fascinating question with a nuanced answer. Electric and hybrid vehicles present unique challenges with their heavy battery packs and different weight distribution compared to conventional cars.

Interestingly, many manufacturers actually choose torsion beam suspension for their electric and hybrid models specifically because of its space-saving design. That compact layout creates more room for battery placement while maximizing interior space—two crucial factors in modern EVs and hybrids.

The inherent stiffness of a torsion beam can actually be beneficial in supporting the additional weight of batteries. As one engineer cleverly noted, "Position bushings behind the wheel in EVs for improved impact harshness and battery protection."

Today's EV torsion beam designs often include specialized damper tuning to handle increased unsprung weight, sophisticated bushing designs with variable compliance, and careful positioning of the beam relative to the trailing arm pivots. All these tweaks help maintain ride comfort despite the additional weight.

Look at pioneering hybrids like the first-generation Toyota Prius and Honda Insight—both successfully used torsion beam rear suspensions, proving this design can work beautifully in electrified applications when properly engineered.

If you're shopping for an EV or hybrid, don't automatically dismiss a model just because it has a torsion beam suspension. What matters far more is how well the entire suspension system has been integrated and tuned for that specific vehicle's characteristics.

Conclusion

As we've journeyed through torsion beam suspension, it's clear this "simple" setup packs more clever engineering than first meets the eye. Whether it's acting as both a suspension arm and a built-in anti-roll bar, or being endlessly reimagined by clever carmakers, the torsion beam keeps proving why it's still a favorite after all these years.

For car buyers and enthusiasts alike, here are the big things to remember:

First, cost-effectiveness is a huge strength. The torsion beam typically saves about €100 per car compared to more complex multi-link setups. That matters, especially if you're shopping for a daily driver where every dollar counts.

Space efficiency is another win. Torsion beam suspensions take up less space underneath the car, which means more headroom, legroom, and trunk space for you. If you’ve ever packed a hatchback to the roof, you know how important that can be.

Don't forget about performance surprises. While the torsion beam sometimes gets a bad rap, cars like the Renault Megane R26 and Hyundai i20 N have shown it can keep up with (or even outshine) more complicated suspensions on the road and track. The secret? Great engineering and careful tuning.

Maintenance is refreshingly simple. With fewer parts to wear out, a torsion beam can be a breeze to keep in shape. Less time at the mechanic means more time on the road (or, let’s be honest, more time for coffee runs and road trips).

And if you like to tinker? Tuning potential is real. Swapping in firmer springs, updating bushings, or even adding a Watts linkage can transform your car’s handling without breaking the bank—or needing a race team in your garage.

So, when you’re choosing between a torsion beam and a multi-link suspension, think about what truly matters to you. If you’re after the last word in handling and ride comfort, a multi-link might be worth the splurge. But if you want a well-rounded, durable, and affordable package for everyday use, a good torsion beam suspension won’t let you down.

At RapidVehicles.com, we know that every suspension style has its place. Whether you drive a BMW with cutting-edge tech or a trusty compact with a humble torsion beam, we’ve got the parts and accessories to help you keep your ride running smoothly—and maybe even a bit sharper than the factory intended. Explore our selection of bushings, springs, and more to keep your car at its best.

The torsion beam suspension might not win any beauty contests in car tech, but it’s the unsung hero that keeps millions of cars practical, affordable, and fun to drive. It’s clever, it’s reliable, and it’s not going anywhere anytime soon.

For more on what’s happening in cars—from supercars to everyday heroes—check out More info about supercar news.

Thanks for reading—and happy driving from all of us at RapidVehicles.com!